The new MKB.V2 braking system

IPKarting Group has always had a special focus on the MINI category, a breeding ground of many younger drivers which, with the new homologation regulated by the International Federation, has acquired further prestige and momentum.

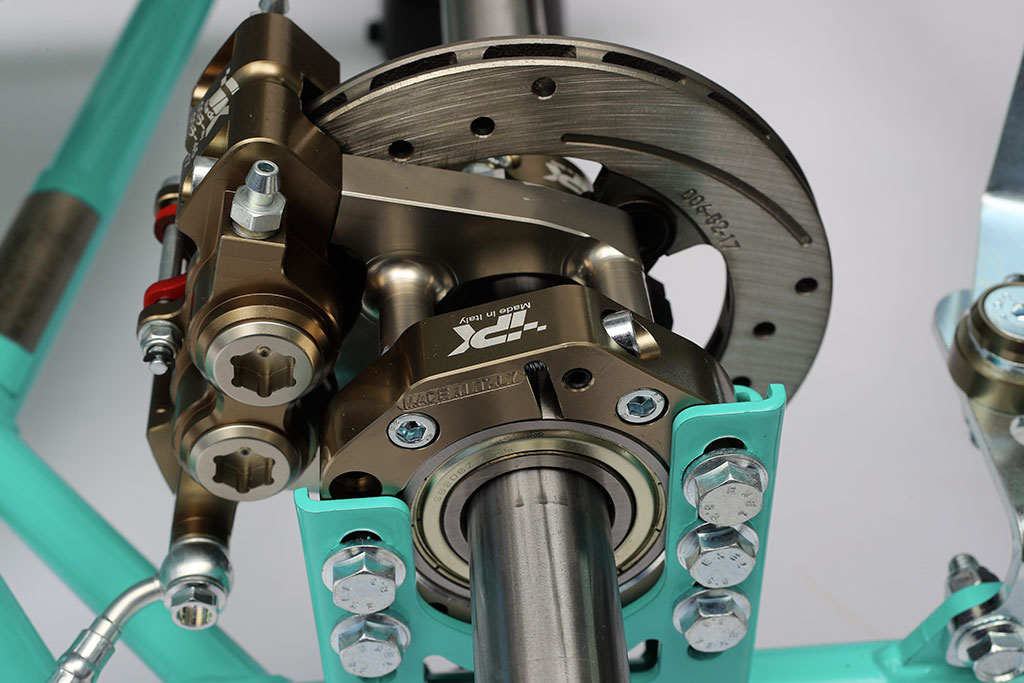

Following the new regulations, IPKarting Group has decided to equip the new Formula K Monster EVO 3 with a new brake system. The result of the experience work of the Research & Development department is the new MKB.V2 system, a product which benefits from a careful choice of materials and the most advanced production technologies.

Let us review the details.

CALIPER

The caliper chosen for the new MINI Formula K kart comes directly from the front caliper that equips KZ karts. It is a caliper with four 19 mm diameter pistons, featuring special grooves which improve heat dissipation.

Minimizing the wheels locking up and improving a more smooth and controlled braking have been the objectives which guided the entire project.

Like all the accessories manufactured by IPKarting, the caliper is rigorously machined from a solid block of metal using numerically controlled machinery in order to minimize its weight. Additionally, the part is carefully designed and focuses on every functional and aesthetic detail.

As far as the assembly is concerned, the company opted for a radial attachment which ensures greater rigidity compared to a traditional attachment.

DISC BRAKE

The pads of the MKB.V2 braking system act on a floating and self-ventilated disc, 149 mm in diameter and 11 mm in thickness. Thanks to a careful study of the drilling and milling processes of its surface, a clear improvement was achieved both in the cooling process and in the cleaning of the pads. This results in a friction between the disc and the pad which remains constant even after repeated use. Additionally, the milling process significantly reduces the risk of cracks and breakage, ensuring greater longevity.

MASTER CYLINDER

The master cylinder plays a crucial role in a braking system, transforming the force applied to pedal into pressure of the pads against the disc. IPKarting knows this very well and for the MKB.V2 it decided to use the same pump installed on karts in the higher categories. Inside it we find a 19 mm piston working, while the stroke recovery tank, located above the cylinder has the task of keeping the brake pedal stroke constant with the wear of the pads. Xeramic DOT 5.1 fluid guarantees longevity and uniform performance as well as optimal viscosity at all operating temperatures.

Like all the other accessories, the master cylinder is machined with numerically controlled machinery and finished with an anodizing treatment.

BRAKING PADS

The wide choice of pads, capable of meeting the needs of any driving style and adapting to the characteristics of any track has long been one of the qualities of IPK Group’s brakes. The solutions available for the MKB.V2 model are these three.

SOFT: this pad has the softest friction material, offers a powerful braking even with little pressure at the expense, however, of a quicker wear period. It is identified by the color green.

MEDIUM: as implied by the name, this pad is the middle ground between the SOFT and the HARD pads. It is no coincidence that it is the pad with which IPK chassis are equipped with as standard. Its adaptability to any track conditions and driving style is the result of the work developed with the drivers of the Group’s official racing team. It is identified by the color red.

HARD: it guarantees a very reduced wear thanks to the hardness of the friction material. It is suitable for those who prefer a gentle braking or are used to applying a lot of pressure on the brake pedal. Its color is blue.